Test Handlers

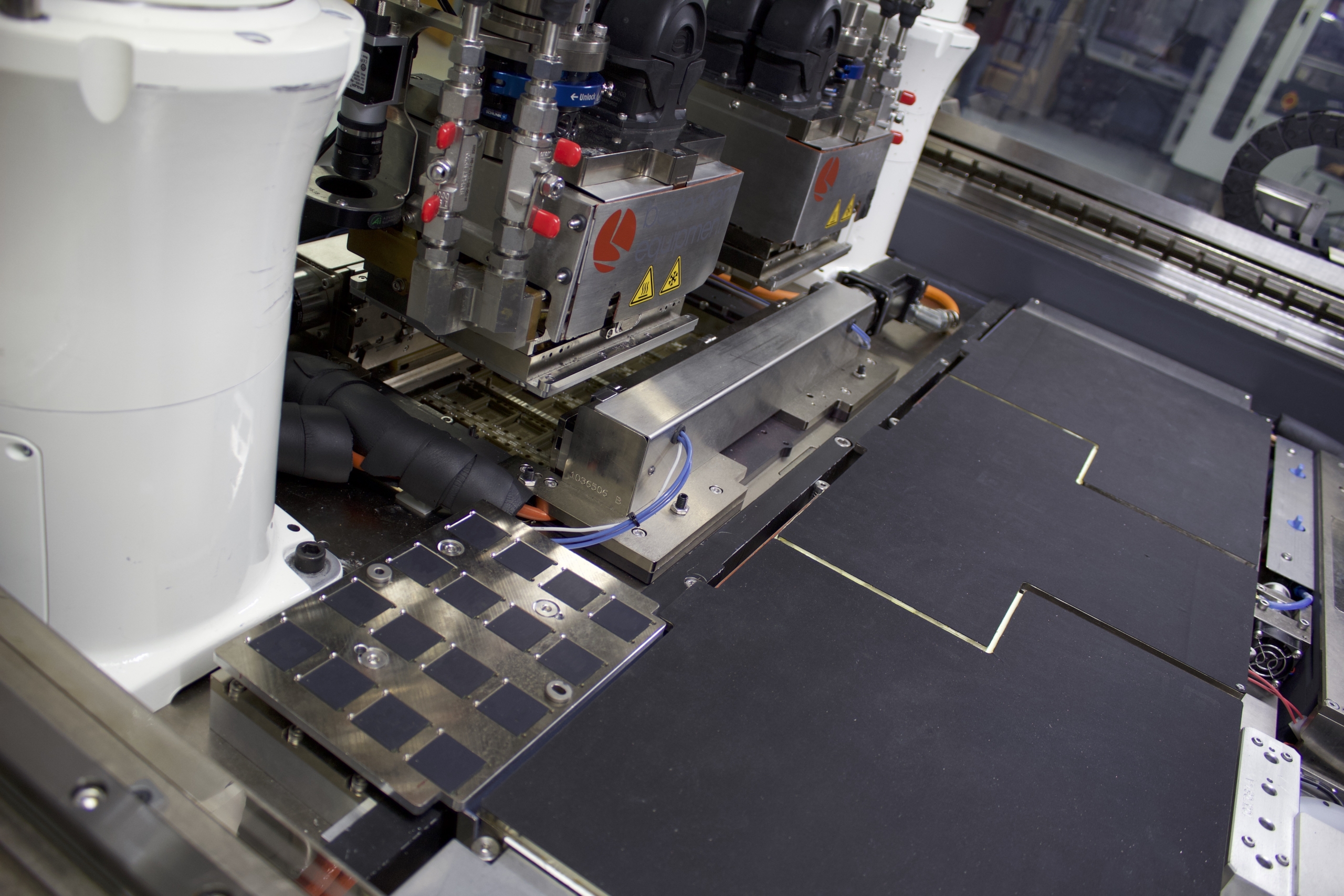

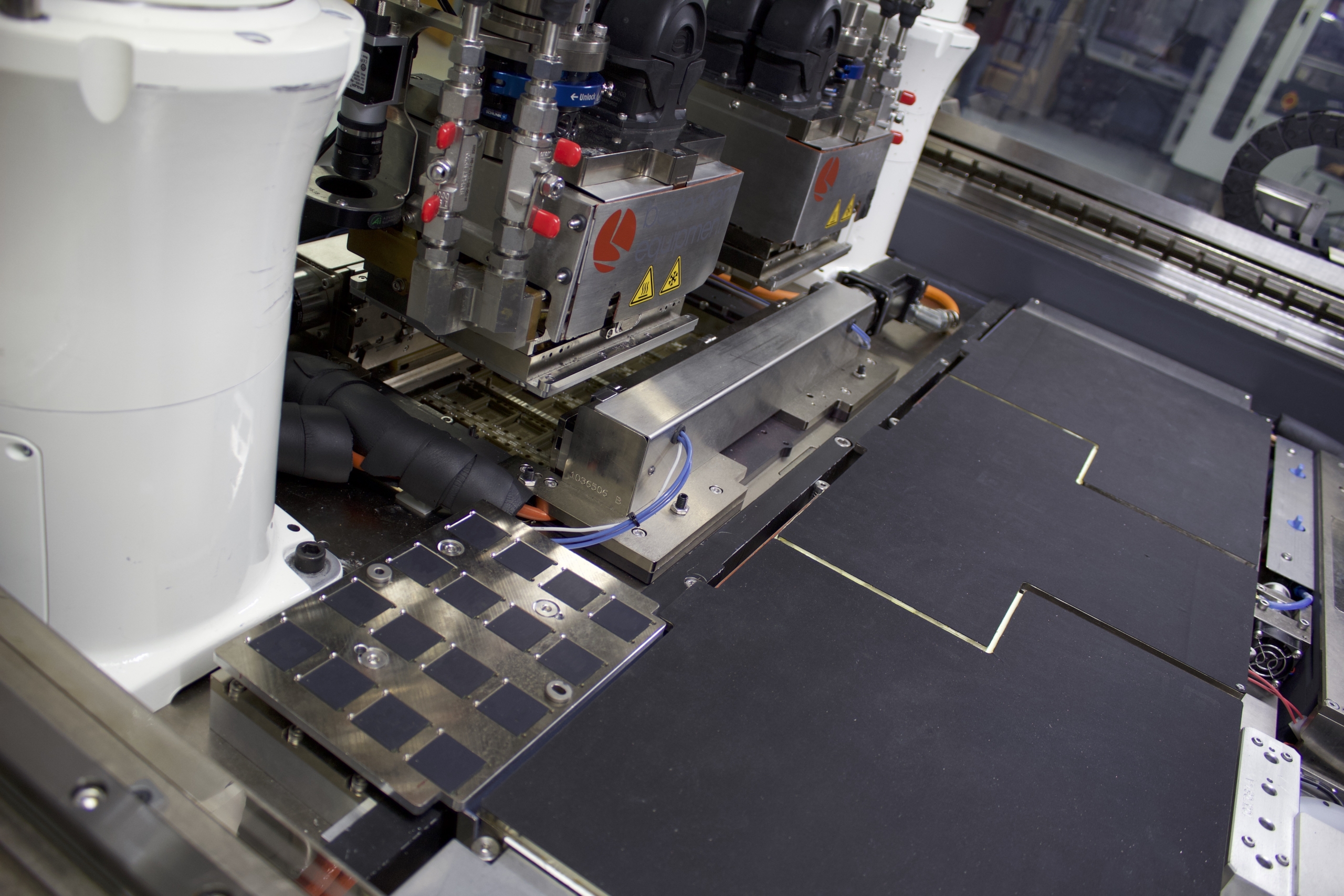

Test handlers from Boston Semi Equipment deliver time-tested, proven performance in packaged semiconductor device testing. Our Zeus gravity product line is installed at customer sites around the world and producing excellent, reliable results day in and day out. The Zeus test handler platform is based on a common core design and is available in thermal test ranges including tri-temp, ambient and ambient/ hot configurations.

We continually add to our product portfolio with customer-focused solutions engineered to solve complex device handling applications. Our newest product line, Panacea, is a totally re-imagined pick-and-place solution like no other on the market today. Panacea offers exceptional value and delivers consistent, reliable production with faster device changeovers, ultimately leading to lower cost of ownership.

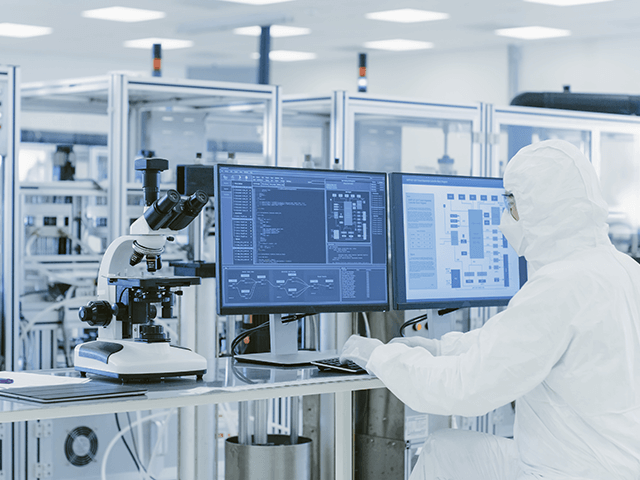

Our global service infrastructure offers rapid response for installation, warranty and post-warranty service to keep our customers running at optimal efficiency.